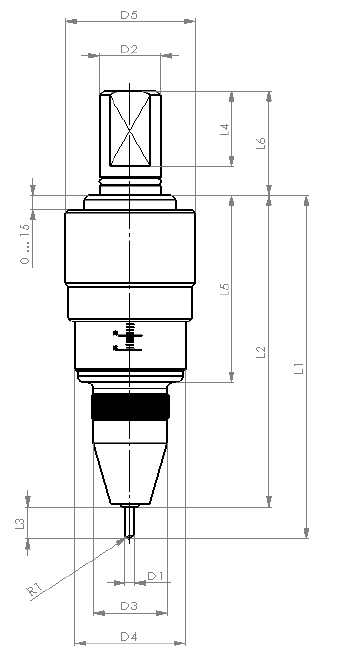

Marking tool

suitable for 20 mm collets and Weldon holders (Weldon holders only when using the function check)

Table of sizes marking needles

| Order No. | D1 [mm] |

D2 [mm] |

D3 [mm] |

D4 [mm] |

D5 [mm] |

L1 [mm] |

L2 [mm] |

L3 [mm] |

L4 [mm] |

L5 [mm] |

L6 [mm] |

Weight [g] |

| AMW-M20 | 3 | 20 | 24 | 36 | 42 | 119 | 108 | 11 | 26 | 65 | 36 | 263 |

Application

This tool is ideal for marking a wide variety of materials such as aluminium, titanium, steel, bronze, copper, brass, plastics etc. Workpiece unevenness of up to 6 mm is compensated for.

- With an eccentric needle:

External cooling is recommended during the marking. The marking speed as well as the spindle speed used can be adapted to the marking according to your own individual wishes and requirements. Select between 3 marking needles: 0.1 mm / 0.2 mm / 0.3 mm eccentricity.In general: The greater the eccentricity and the higher the spindle speed (or the lower the feed rate), the deeper is the marking. The following rule of thumb applies for a clean text: Feed (mm/min) x 10 = Spindle speed (rpm)

- With centric needle:

External cooling is not necessary during the marking. The maximum marking speed: maximum feed rate. Select between 2 marking needles: 0.5 mm / 1 mm radius at the needle tip (R1).- Needle M20N-90R10 Ex00 is optimal for marking with a large font (font size legible from 5 mm) and wide line thickness on surfaces with a hardness of up to 50 HRC.

- Needle M20N-90R05 Ex00 is optimal for marking with a small font (font size legible from 2.5 mm) and medium, but deeper line thickness on surfaces with a hardness of up to 55 HRC.

Marking needles are not included.

Features

The M20 has high-quality guides and a robust special needle. The setting is made continuously through a knurled nut and can be determined by means of a 0-15 scale. Due to this setting capability with the knurled nut, the tool is optimally suited for small and medium lot sizes. The tool is held preferably in 20 mm collets or Weldon holders. When using the function check, use of Weldon holders is mandatory.

Features

- Lightning-fast needle change: the marking needle is removed and changed with the aid of a pliers. This is an advantage even when the needle is worn or broken off.

- More distinct marking through use of an eccentric needle: with the MarkingStar you have the ability to select between conventional rolling and rotary swaging. In rotary swaging, the material is compressed, as well as forced sideways, and "swaged" by the rotation of the marking needle. This requires use of an eccentrically ground needle which, in combination with spindle rotation, creates more distinct marking than conventional rolling.

- Function check for use in automation: An integrated function check makes the MarkingStar suitable for use in automation. The query takes place via a pneumatic dynamic pressure query. For this purpose, the tool machine needs an internal coolant supply (ICS) and freely, acknowledgeable M command.

- Maximum flexibility thanks to lightning-fast changes between various needle types

- Extremely high wear resistance

- Suitable for marking a wide variety of materials

- Easy adjustment by means of a knurled nut (possible also when clamped)