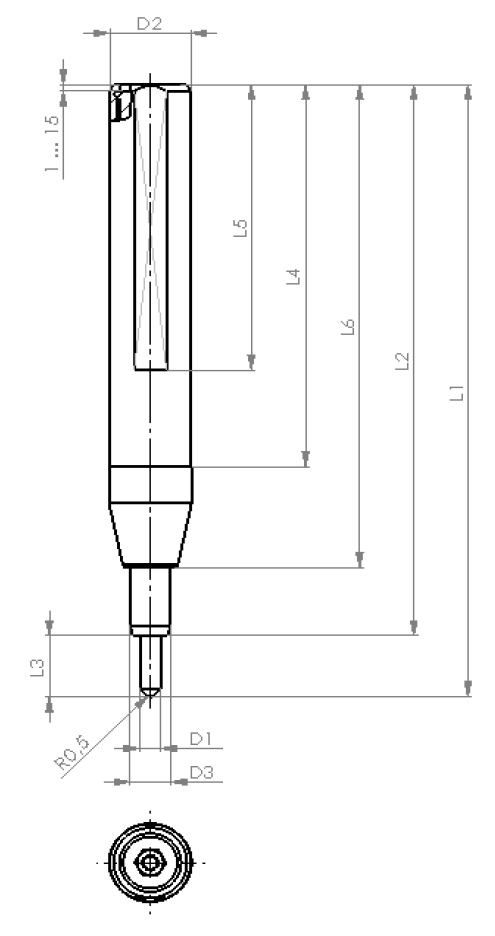

Marking tool with long, narrow tip

suitable for 12 mm collets and Weldon holders

Table of sizes marking needles

| Order No. | D1 [mm] |

D2 [mm] |

D3 [mm] |

L1 [mm] |

L2 [mm] |

L3 [mm] |

L4 [mm] |

L5 [mm] |

L6 [mm] |

Weight [g] |

| AMW-MML12 | 3 | 12 | 6 | 95 | 86 | 9,5 | 59 | 44 | 75 | 26 |

Application

The tool is especially well-suited for marking in a very confined spaces. A wide variety of materials such as aluminium, titanium, steel, bronze, copper, brass, plastics etc. can be marked. Workpiece unevenness of up to 9 mm is compensated for.

Two needle types are available:

- Needle MML12N-90R05 Ex00 is optimal for marking with a small font (font size legible from 2.5 mm) and medium line thickness on surfaces with a hardness of up to 55 HRC.

- Needle MML12N-90R03 Ex00 is optimal for marking with a small font (font size legible from 1.5 mm) and small, but deeper line thickness on surfaces with a hardness of up to 57 HRC.

The maximum marking speed depends on the feed rate of the machine.

Marking needles are not included.

Features

The MarkingStar MML12 has high-quality guides and a robust special needle. It has an outstanding narrow tip. Setting occurs steplessly via an inside screw, which can be adjusted using a hexagon wrench. Because this tool has to be removed from the holder in order to be set, it is optimally suited for large-scale production. The tool is preferably received into 12 mm collets or Weldon holders.

Advantages

- Lightning-fast needle change: the marking needle is removed and changed with the aid of a needle. This is an advantage even when the needle is worn or broken off.

- Maximum flexibility thanks to lightning-fast changes between various needle types

- High wear resistance

- Suitable for marking a wide variety of materials

- Very compact design

- Long, narrow tip for use in confined spaces (e.g. in grooves)